Hi-Q Products

STARLOX

Starlox specification

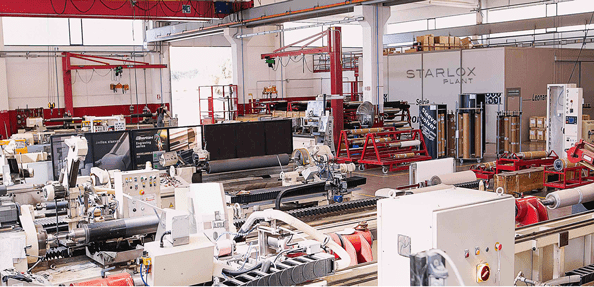

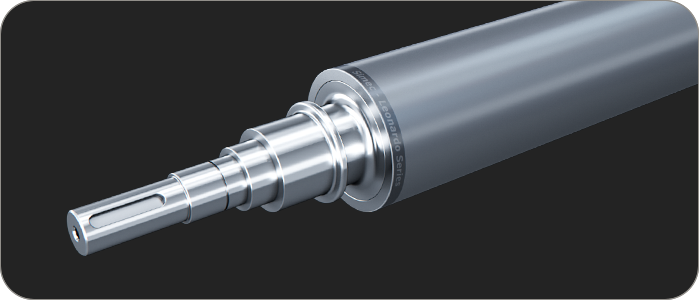

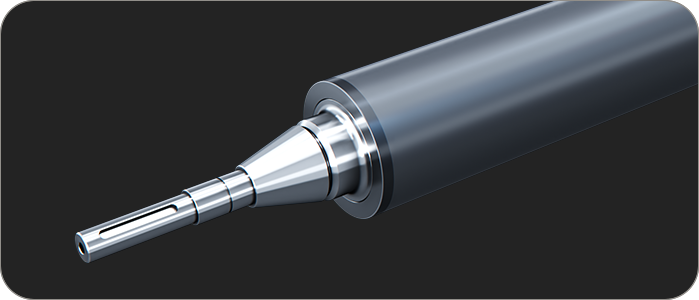

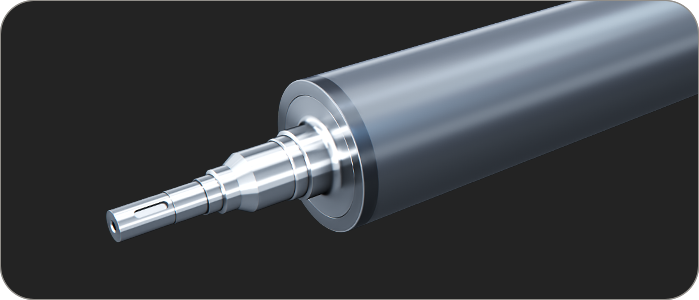

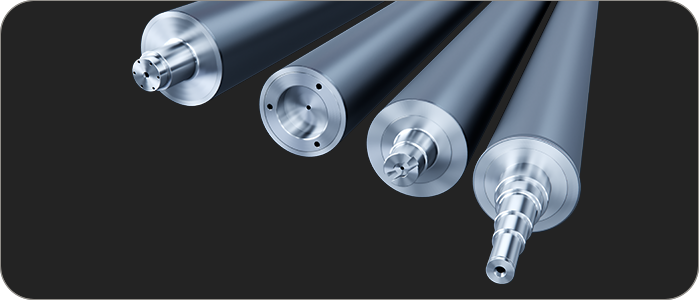

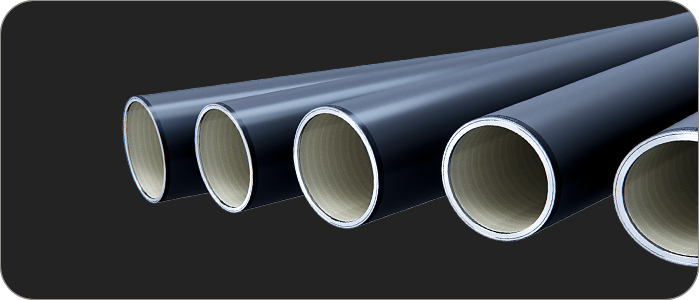

1987. We pioneer laser engraving into ceramics. The production hub in Montefino equipped with 14 Fiber Laser machines is dedicated to this process and controls the entire production process. The anti-corrosive and ceramic coatings are customized by industry. To meet specific needs the anilox specs most suitable for the new concept printing presses have been selected, tested and codified. Diameters up to 800 mm, lengths up to 7000 mm.

STARLOX Specifications

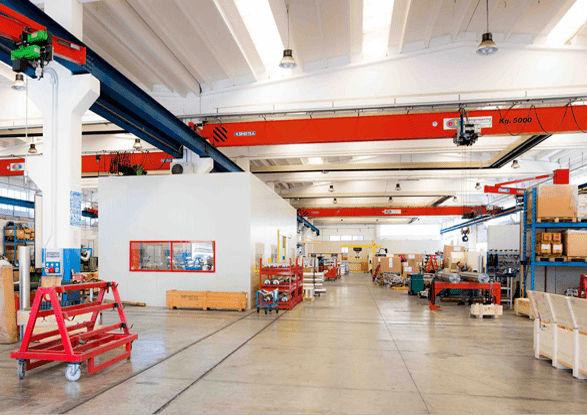

Simec Group pioneered laser engraving into ceramics. The production hub in Montefino which covers a 12,000 sqm roofed area, is dedicated to this process and controls the entire production process. The anti-corrosive and ceramic coatings are customized by industry. The construction and engraving characteristics most suitable for the new concept printing presses have been selected, tested and codified: our anilox are designed to meet specific needs. 14 Fiber Laser machines. Diameters up to 800 mm, lengths up to 7000 mm, weights up to 5 tons.

The coating Specialists

The coating Specialists

Partnership

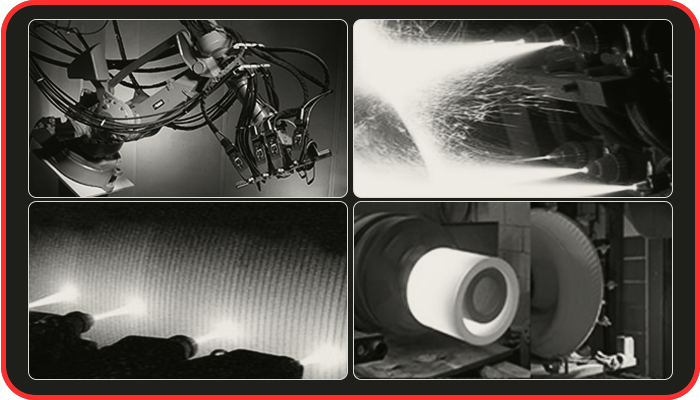

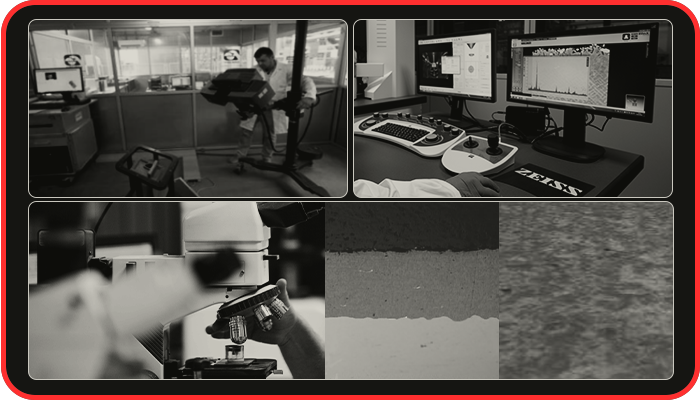

The technological partnership with Flame Spray dates back to 1987. Together with them, who have been operating in the coating industry for 50 years and are world leaders in this sector, we have created a production unit in Montefino dedicated to this process. Experience, skills and deep market knowledge allow us to offer our customers anilox with coatings developed ad-hoc to meet the specific needs of each industry.

TECHNOLOGIES

Flame Spray operates in several application fields including Energy, Oil, Aeronautics, Aerospace and Corrugated; together, we offer OEMs and end users a TOP CLASS combination of technology and know-how. We are able to select the most suitable materials and technology for each product offered, while benefiting from significant economies of scale. We can count on a dedicated R&D for coatings, strategic to ensure the excellence of our products.

QUALITY

The quality of our anilox is strongly influenced by the condition of the ceramic coating into which we are engraving. In order to guarantee a high quality level for each roller and considering the extremely heterogeneous structures and dimensions we process, it is necessary to rely on specialized laboratories and staff. The structure of Flame Spray allows us to inspect the characteristics of the coatings at every stage of the production cycle.

Product and process excellence

Product and process excellence

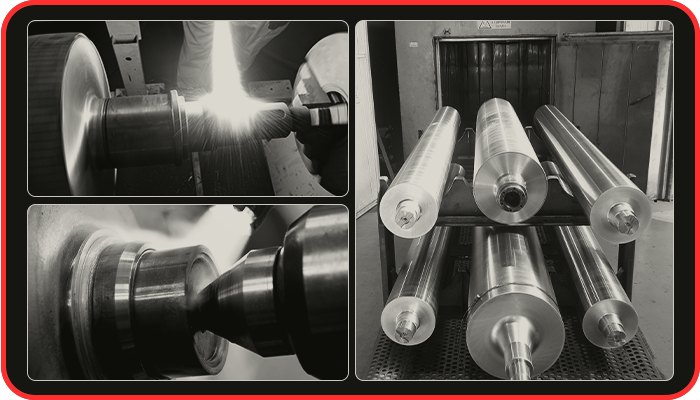

NEW SUPPLY

The rigorous selection of raw materials, the in-house management of most of the processing and the control of the entire production cycle allow us to offer products that perfectly meet the specific requirements of each industry we serve. Our production equipments allow us to manufacture and engrave anilox up to 7000 mm of engraved table. Factory digitization and automation lead to the creation of predictive warehouses with reduction of waiting times.

REFURBISHED

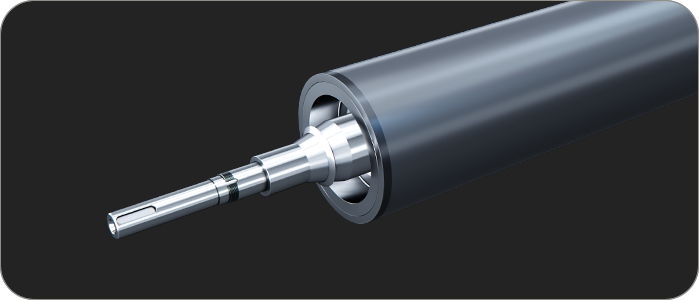

Our procedures ensure that a refurbished anilox has the same performance and working life as a new one. The complete removal of the ceramic and any other coatings is an essential step to ensure that the re-engraved product performs and is as durable over time as a new one: for us, this is a standard procedure. Each anilox comes with an ID card on which all significant steps in the lifecycle are recorded, allowing us to analyze its performance from the cradle to the grave.

PRODUCTION CODING

All production steps have a barcode to be scanned at the beginning and end of the process. This system allows us to customize production cycles according to each industry specific needs, to identify the processing status of every piece at any time, to reproduce the same specifications over the years using also the same production tools thus ensuring repeatability of the work and to create warehouses fed with ready-to-be-shipped anilox.

Which is the correct Anilox for you?

Which is the correct Anilox for you?

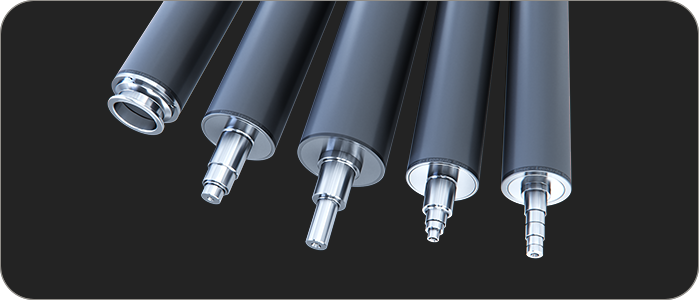

FLEXIBLE PACKAGING

To the operators of the flexible packaging industry we offer 100% Made in Simec Group laser engraved products with specialization in sleeves. Our anilox are designed for optimizing the performance of the flexographic printing presses: we guarantee results that meet customers’ expectations, high quality standards, durability and repeatability. Fast deliveries thanks to our predictive warehouses.

LABELS

We count on dedicated state-of-the-art production lines, enabling us to offer products with optimal ink release and extended service life. Not just a roll, but the anilox that maximize flexo press performance: we guarantee results that meet customer’s expectations and repeatability. Fast supplies and prompt delivery thanks to our predictive warehouses.

SACKS AND BAGS

In addition to the wide range of screens available, we can develop custom-made engraving configurations to meet the specific needs of companies in this industry sector. For printers of paper sacks and bags using three-roll in-line systems, we offer various geometries up to 220 lines per centimeter.

COATING AND LAMINATION

To those customers who prefer laser engraved ceramic rollers, we can offer rolls with engraved length up to 7000 mm and a wide range of engraving geometries. We have developed ad-hoc substrates applied by Thermal Spray technology or different welding technologies between the iron base of the roller and the ceramic coating.

CARDBOARD PRINTING

To the operators of the corrugated cardboard printing industry we offer high quality cylinders with no size limitations: diameters up to 800 mm, engraved length up to 7000 mm, weight up to 5 tons. We have developed geometries able to enhance printing quality and increase versatility; our anilox are engineered to maximize the performances of the most advanced flexographic printing presses.

TISSUE PRINTING

We directly control the entire production cycle of our aniloxes, imposing strict tolerances to guarantee a high quality level. The anti-corrosive and ceramic coatings as well as the engraving specs are developed to meet specific industry needs and ensure optimal results and jobs repeatability. Thanks to our proactive approach, powered by SDB, we offer deliveries faster than ever.

FLEXIBLE PACKAGING

To the operators of the flexible packaging industry we offer 100% Made in Simec Group laser engraved products with specialization in sleeves. Our aniloxes are designed for optimizing the performance of the flexographic printing presses: we guarantee results that meet customers’ expectations, high quality standards, durability and repeatability. Fast deliveries thanks to our predictive warehouses.

Etichette

Sacchi & Sacchetti

Spalmatura & Laminazione

Stampa cartone ondulato

Stampa Tissue

© 2019 Simec Group Srl Via Verga, 17 – 21057 Olgiate Olona (VA) – +39 0331 393900

Share Capital Euro 2.000.000,00 i.v. – R.E.A Varese n. 335797 – VATIN: IT03252460120