Anilox Cleaning

Cleaning Systems

Anilox Cleaning

Cleaning Systems

Proper maintenance of anilox translates into longer life and better ink release resulting in increased stability and certainty of print repeatability. This is why we have designed, developed and patented dry and liquid cleaning systems, to meet the different market requirements without losing sight of the importance of protecting the environment and the operators.

Proper maintenance of anilox translates into longer life and better ink release resulting in increased stability and certainty of print repeatability. This is why we have designed, developed and patented dry and liquid cleaning systems, to meet the different market requirements without losing sight of the importance of protecting the environment and the operators.

PROtect&care - Liquid System

PROFIL - Dry System

A cleaning head for every need

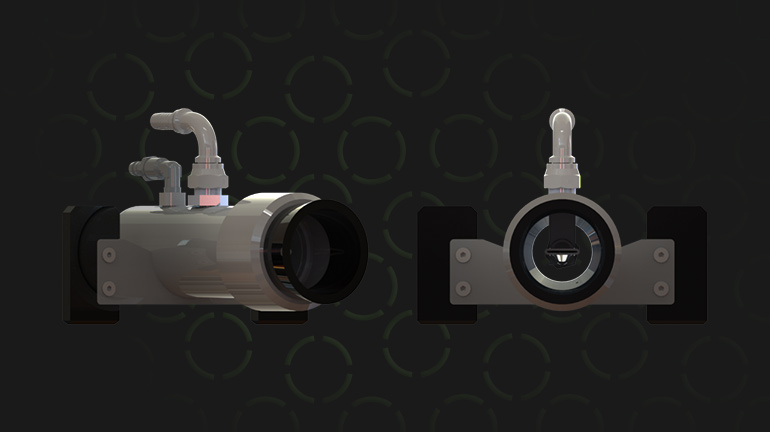

Liquid cleaning system

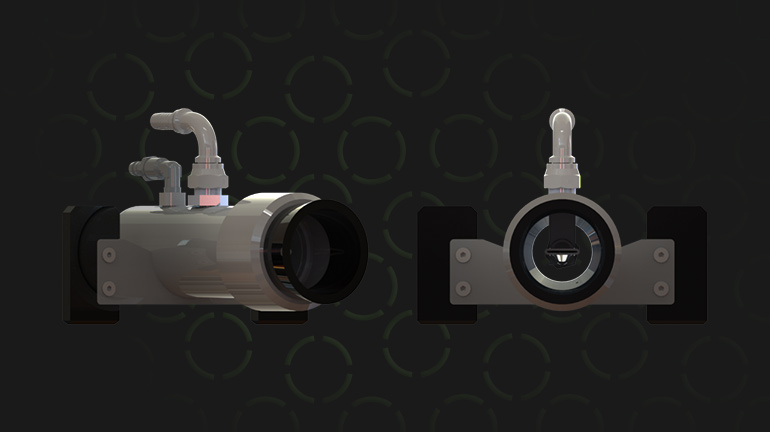

The liquid cleaning head is patented technology. The containment blade allows for watertight cleaning. Available in different sizes and with interchangeable parts, it fits perfectly to different diameters.

Liquid cleaning system

The liquid cleaning head is patented technology. The containment blade allows for watertight cleaning. Available in different sizes and with interchangeable parts, it fits perfectly to different diameters.

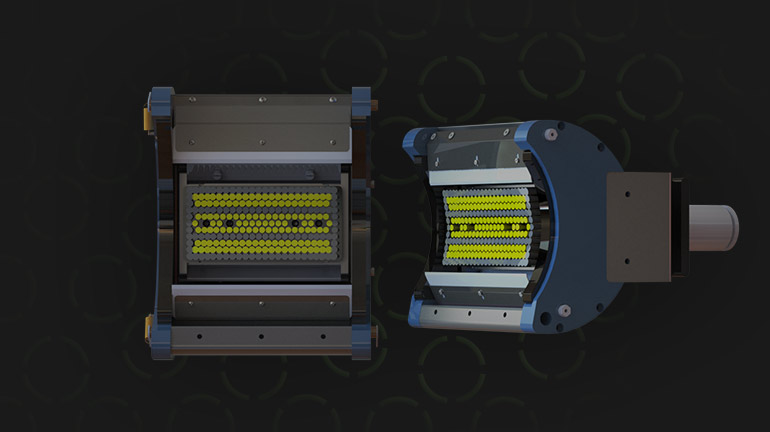

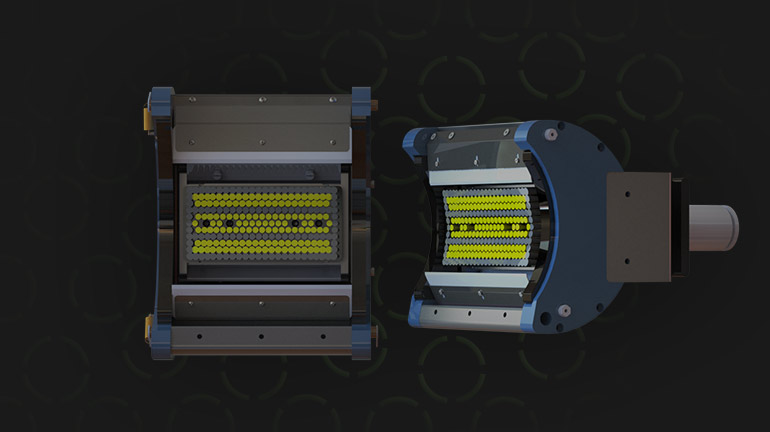

Dry cleaning system

The dry cleaning head throws out baking soda, eliminating any risk for the anilox and avoiding dust spillage around the machine thanks to the simultaneous suction action.

Dry cleaning system

The dry cleaning head throws out baking soda, eliminating any risk for the anilox and avoiding dust spillage around the machine thanks to the simultaneous suction action.

© 2019 Simec Group Srl Via Verga, 17 – 21057 Olgiate Olona (VA) – +39 0331 393900

Share Capital Euro 2.000.000,00 i.v. – R.E.A Varese n. 335797 – VATIN: IT03252460120