Prodotti Hi-Q

CABOLL

Caboll is a project starter back in 1995 and now is the new Simec branded product line which goes with the 4 historical brands of the company and further expands Simec areas of interest and activity. This new product has involved important investments in technologies, machinery and dedicated infrastructures and is already able to meet the technical and dimensional requirements of all the markets where Simec operates as well as most of the new ones where this product has already been tested and is ready to be introduced into the production chain.

CABOLL, anilox Special Coating

CABOLL is a project starter back in 1995 and now is the new Simec branded product line which goes with the 4 historical brands of the company and further expands Simec areas of interest and activity. This new product has involved important investments in technologies, machinery and dedicated infrastructures and is already able to meet the technical and dimensional requirements of all the markets where Simec operates as well as most of the new ones where this product has already been tested and is ready to be introduced into the production chain.

What is CABOLL?

CABOLL will bring great technical and economic benefits to end users as well as to machine builders in terms of both performance and periodic maintenance, all while containing costs and in some versions of the product also with important environmental benefits by adopting the green version to replace hexavalent chromium coatings.

CABOLL Application

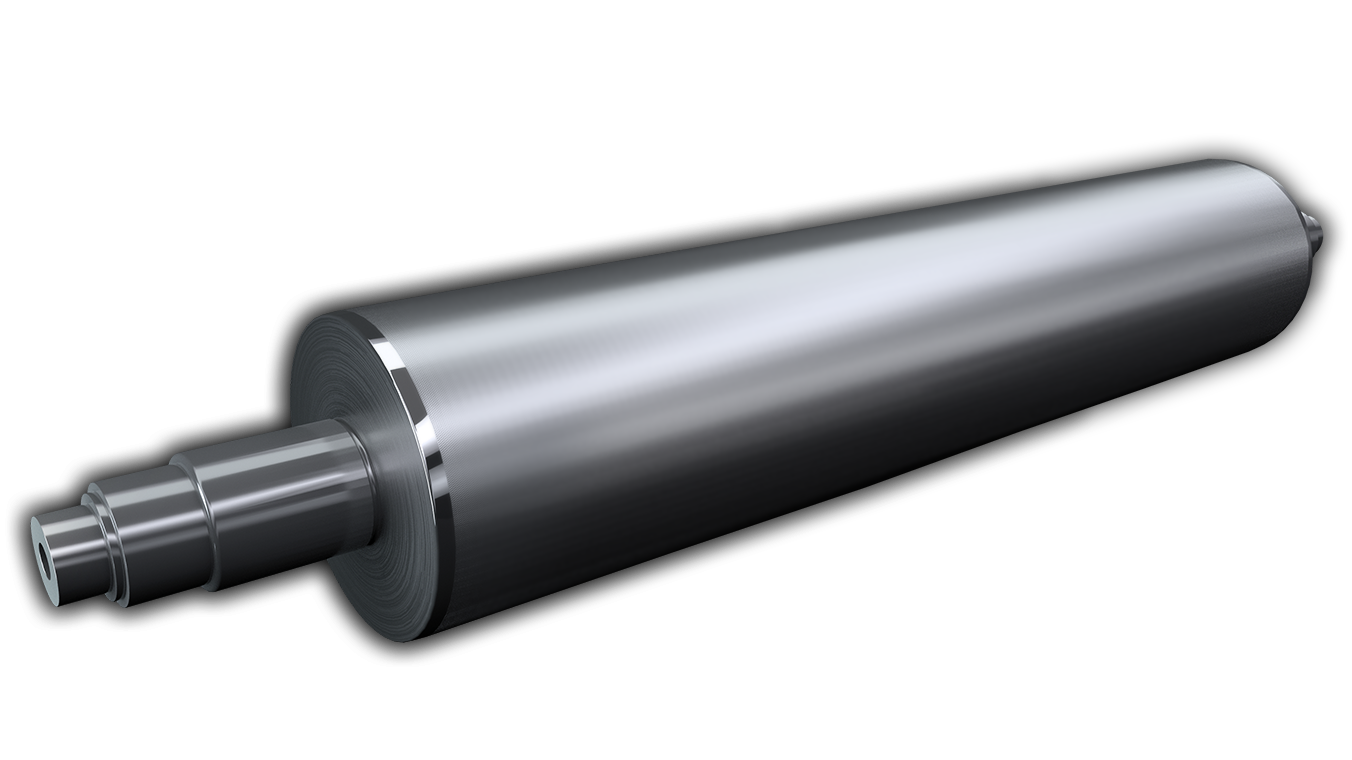

CABOLL - MIRR

Suitable for various types of smooth rollers that are normally protected with chrome coatings in various thicknesses and degrees of finish to suit the application they are destined to.

The same product can be used for all sliding rollers that are currently protected with chrome plating or anodising treatments, thus increasing their life and also solving electrostatic current discharge problems.

| MIRR/GREEN | MIRR | |

|---|---|---|

| Coating thickness | 0,06-0,15 mm | 0,1-0,15 mm |

| Coating hardness | 1100 hv | 1250 hv |

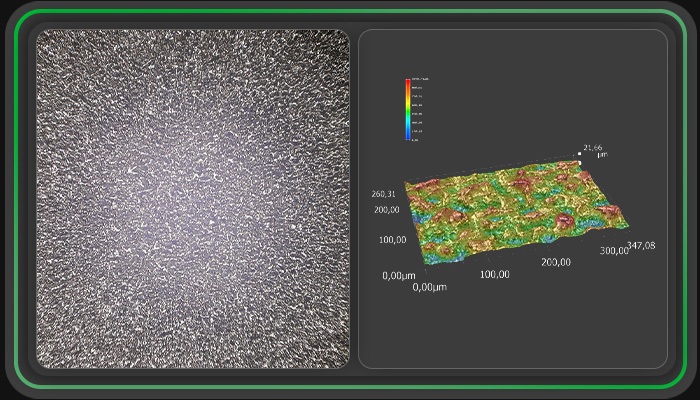

CABOLL - SAND

It can replace all types of chrome-plated + sandblasted rollers.

It is an alternative process to traditional substrates with thicknesses ranging from 0.1 to 0.2 mm of galvanic chrome as well as micro-structured substrates with pre and post treatment sandblasting processes.

| Coating thickness | 0,1 / 0,25 mm |

| Coating hardness | 1250 hv |

CABOLL - ANTI STICK

For all those applications where the microstructure of the surface requires anti-stick characteristics, we can use CABOLL Sand as an anchoring surface for anti-adherent coatings such as Teflon, in order to guarantee a greater resistance of the product to abrasion.

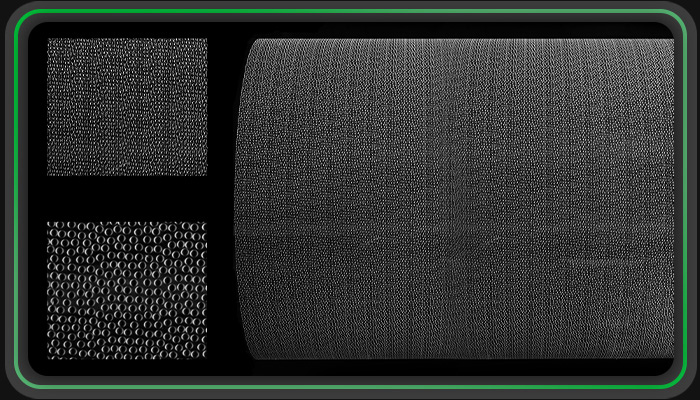

CABOLL - MICRO STRUCTURED

In many applications, in addition to the need for wear and abrasion resistance, specific texturing is required.

Depending on use, there are several different machining processes on different materials, such as copper or steel, which are then coated with chromium plating in thicknesses from 10 to 40 microns.

This product version involves the application of a variable substrate of CABOLL which is then processed according to the structural specifications required by the customer.

| Coating thickness | 0,1 / 0,3 mm |

| Coating hardness | 1250 hv |

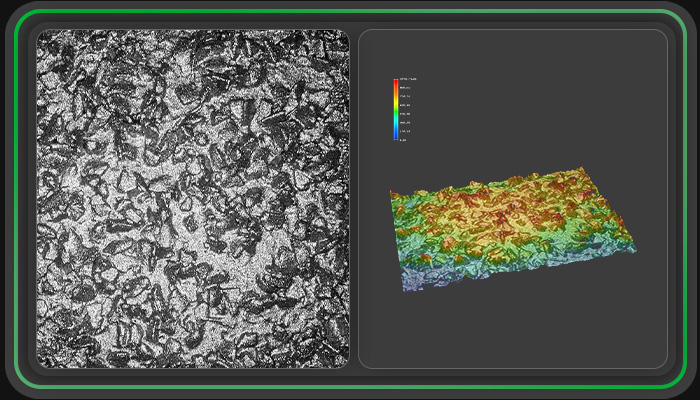

CABOLL - GRIND

Ideal for those applications where an abrasive or high friction coefficient structure is required; widely used in the rubber sector, both for removal purposes and for applications where it is necessary to have rolling grip while maintaining excellent resistance to abrasion.

This coating is quite innovative as we can apply our Caboll directly onto the roller base in a controlled and repeatable manner with predefined structures or create new ones according to specific customer requirements.

| Coating thickness | 0,1 / 0,5 mm |

| Coating hardness | 1350 hv |

CABOLL - COATED

| Coating thickness | 0,03 / 0,08 mm |

| Coating hardness | 1350 hv |

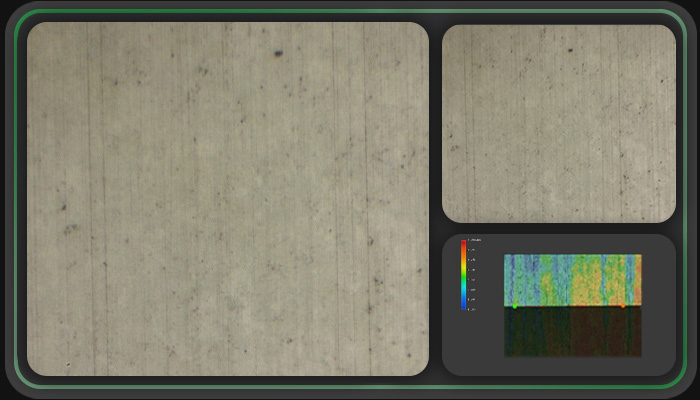

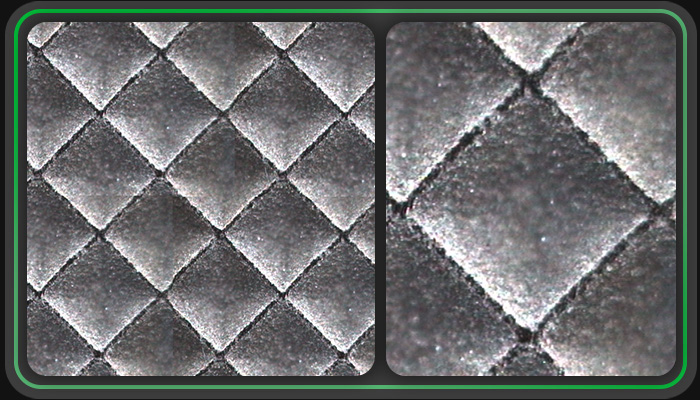

CABOLL - PRINT

This product will bring important technical benefits such as:

higher release coefficient compared to mechanically or electronically engraved chrome-plated rollers, as well as laser engraved ceramic rollers with consequent direct benefits:

– drastic reduction of cleaning cycles

– increased printing or transfer densities

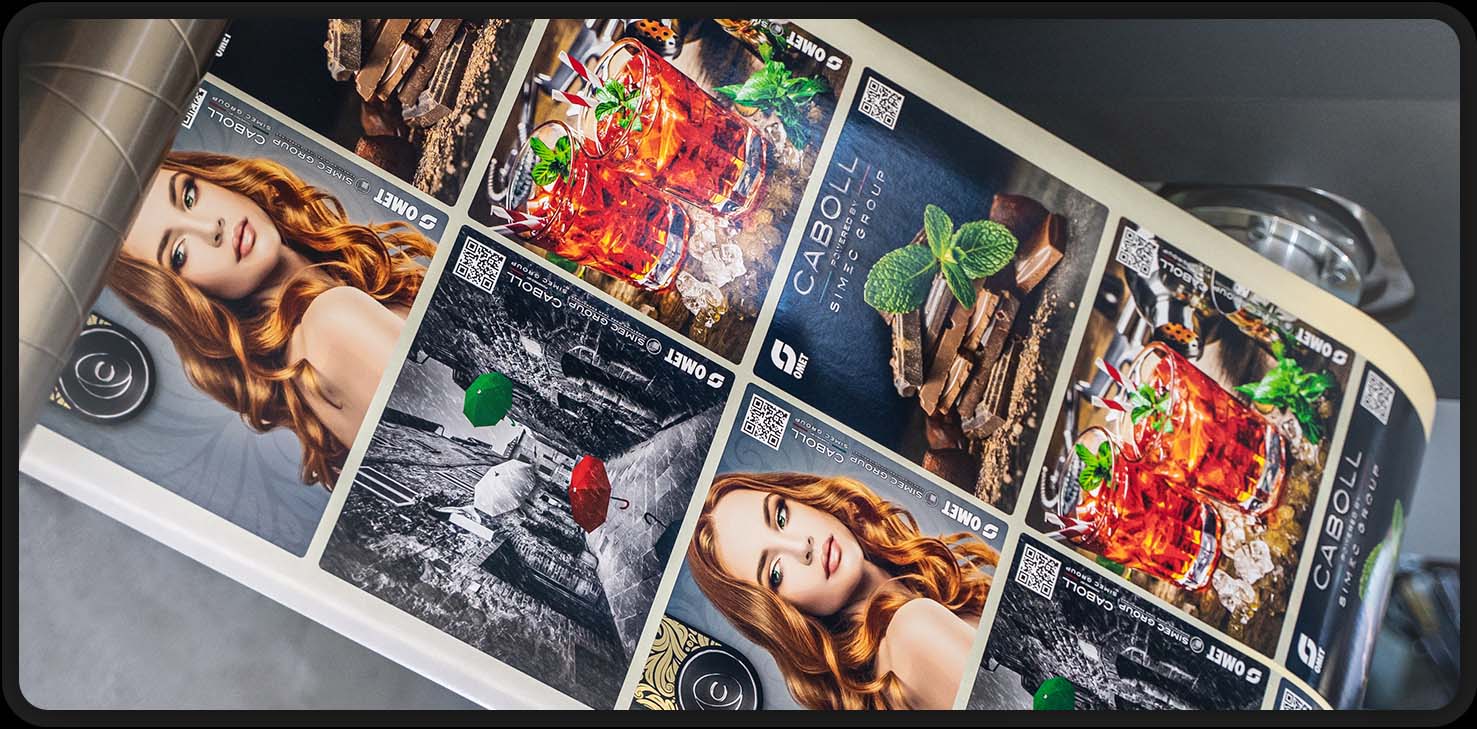

Hi-Q Label

The printing of self-adhesive labels counts today on a new allied, CABOLL. Proposed in test at OMET Printing, it surprised from the very first printed meter. Excellent release capacity, dot definition, reduced printing surface and easy cleaning.

First application served: Hi-Q labels

The printing of self-adhesive labels counts today on a new allied, CABOLL. Proposed in test at OMET Printing, it surprised from the very first printed meter. Excellent release capacity, dot definition, reduced printing surface and easy cleaning.

© 2019 Simec Group Srl Via Verga, 17 – 21057 Olgiate Olona (VA) – +39 0331 393900

Share Capital Euro 2.000.000,00 i.v. – R.E.A Varese n. 335797 – VATIN: IT03252460120