Labels

Industries Served

Labels

Industries Served

Labels

We offer rollers and sleeves of the highest quality and 100% Made in Simec Group. We have a state-of-the-art dedicated coating line: coating density and high hardness improve ink release and extend operating life. We constantly implement our predictive warehouses with anilox perfectly matching our customers’ needs to offer supplies faster than ever.

We offer rollers and sleeves of the highest quality and 100% Made in Simec Group. We have a state-of-the-art dedicated coating line: coating density and high hardness improve ink release and extend operating life. We constantly implement our predictive warehouses with anilox perfectly matching our customers’ needs.

STARLOX for Labels

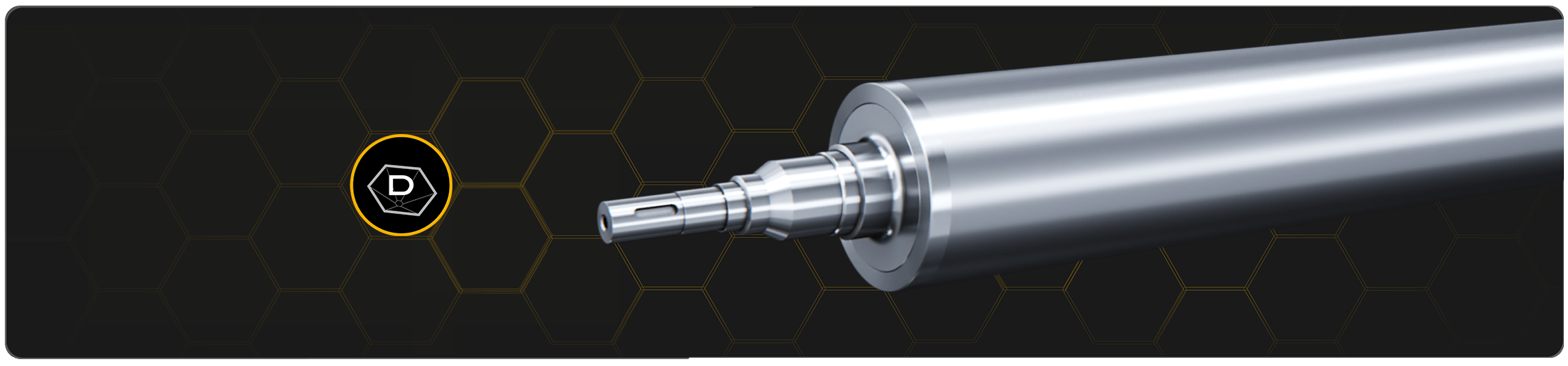

Our anilox are manufactured in-house. We engrave our rolls with 500-watt Fiber Lasers and count on a fleet of 14 machines. Thanks to our factories lean organization, SDB system and the automated work station with CNCs and a robotic arm, we are able to maintain a permanent stock of rollers perfectly responding our customers’ needs.

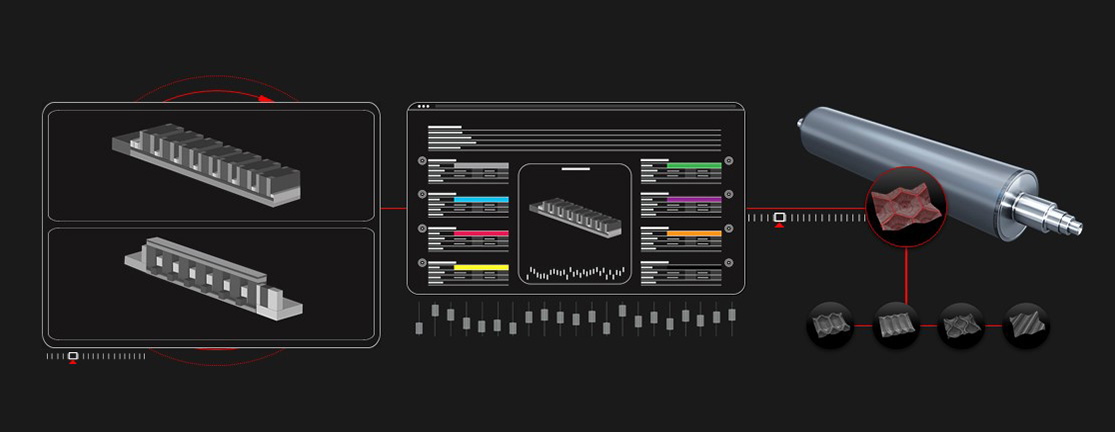

Product customization

Full control of the entire production cycle as well as the technologies at our disposal allow us to identify the most suitable materials and to employ dedicated lines to respond to the sector needs. Pre-selected, tested and validated anilox specifications for each machine model reduce the risk related to their selection. Thanks to our Simec Digital Background we ensure standardization where useful, customization when necessary, high quality and jobs repeatability.

Company

SDB

Our ERP, a tool for your business

We transformed the traditional reactive approach into a proactive one thanks to our ability to predict our customers’ needs in qualitative and quantitative terms.

Purchasing Options

STARLOX for Labels

Our anilox are manufactured in-house. We engrave our rolls with 500 watt Fiber Lasers and count on a fleet of 14 machines. Thanks to our factories lean organization, SDB system and the automated work station with CNCs and a robotic arm, we are able to maintain a permanent stock of rollers perfectly responding our customers’ needs.

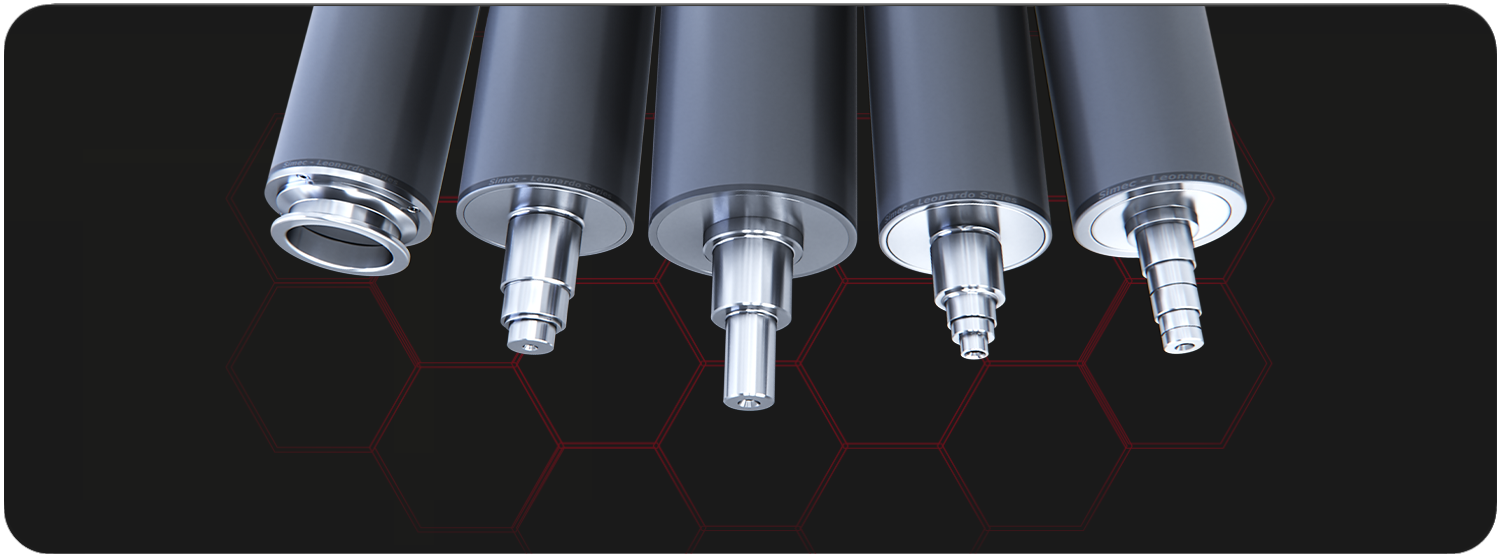

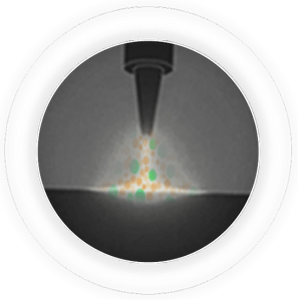

Engraving

Hexagon

Engraving

Double Cell

Engraving

Triple Cell

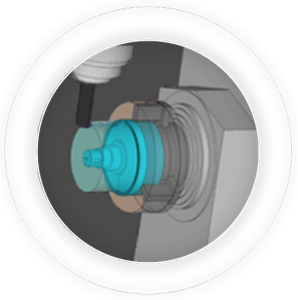

How is it made? Quality needs 16 steps.

We control the entire production cycle. The raw materials are purchased according to surface processing requirements and the OEM’s specifications. We manufacture the journals in our factories based on precise production standards and in accordance with construction drawings. All 16 processing steps were developed to meet the needs of the industry for which the rolls are intended. A barcodes system allows us to identify the processing status of each piece and to reproduce the identical cycle over time. We systematically optimize machining operations through the analysis of the users’ feedback and the data collected during the incoming inspection.

PHASE 01

Component outsourcing

PHASE 02

Journal manufacturing

PHASE 03

Tube roughing out

PHASE 04

Tube trimming

PHASE 05

Journal assembly

PHASE 06

Sides chroming

PHASE 07

Grinding

PHASE 08

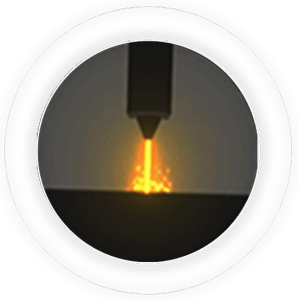

Thermal treatment

PHASE 09

Anticorrosive coating

PHASE 10

Ceramic coating

PHASE 11

Sealing

PHAS E12

Pre-engraving grinding

PHASE 13

Lapping

PHASE 14

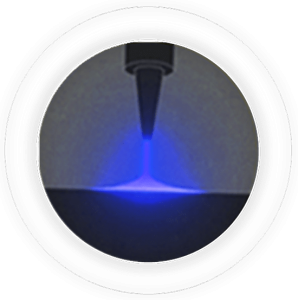

Laser engraving

PHASE 15

Super finishing

PHASE 16

Inspection

Customized engraving according to the printing machine

Our experience with OEMs and leading Groups has enabled us to identify engraving specifications capable of maximizing the performances of the printing presses, of extending the service life of our aniloxes and of reducing ordinary maintenance. Pre-selected, tested and validated parameters for each printing press reduce the risk of anilox selection. Thanks to our Simec Digital Background we ensure standardization where useful, customization when necessary, high quality and jobs repeatability.

Company

SDB

Our ERP, a tool for your business

We have transformed the traditional reactive approach into a proactive one thanks to our ability to predict our customers’ needs in qualitative and quantitative terms. We know exactly what to provide to meet a specific need and we keep stocks to ensure prompt delivery.

Purchasing Options

You might also be interested in

Coating & Lamination

© 2019 Simec Group Srl Via Verga, 17 – 21057 Olgiate Olona (VA) – +39 0331 393900

Share Capital Euro 2.000.000,00 i.v. – R.E.A Varese n. 335797 – VATIN: IT03252460120