Prodotti Hi-Q

EMBOSS

EMBOSS specifications

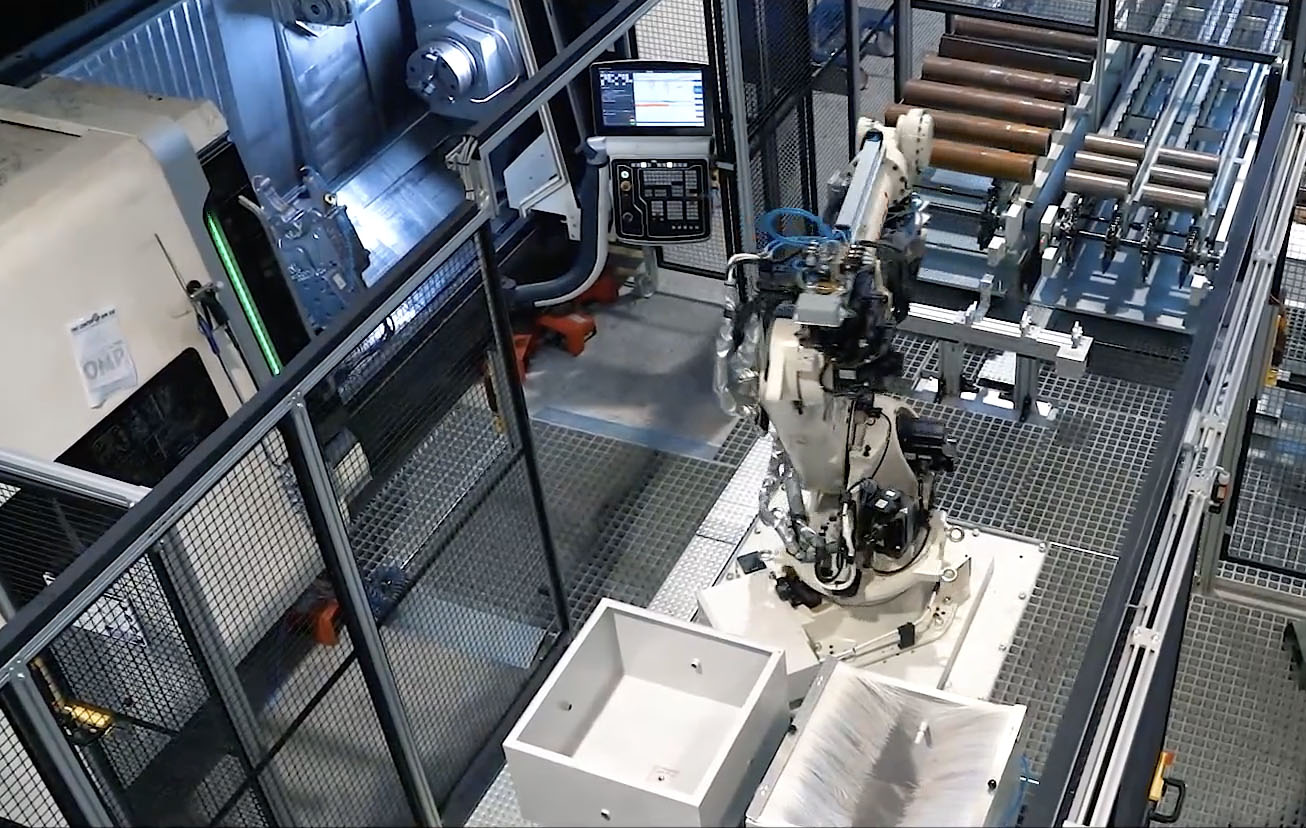

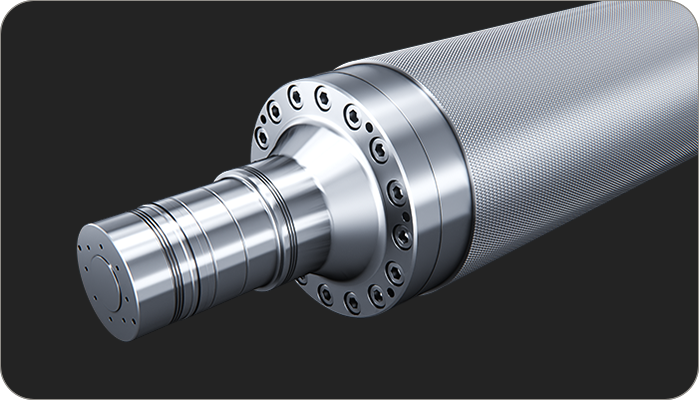

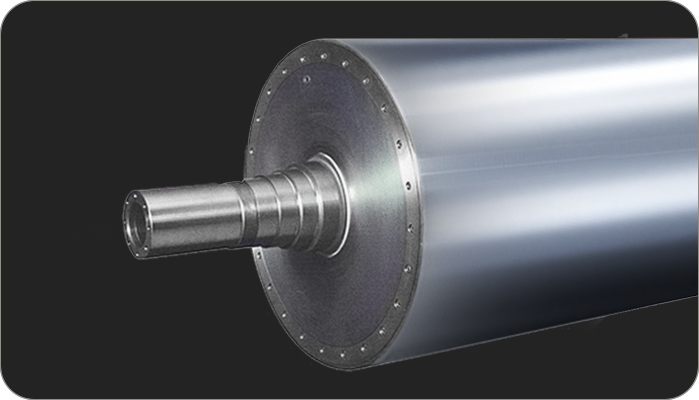

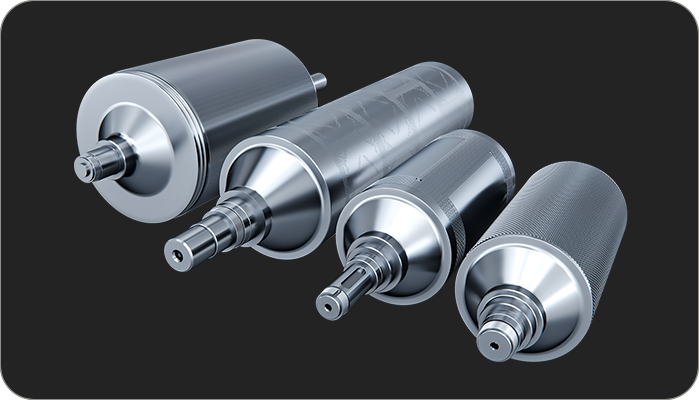

We offer solutions for any production need by developing technical-functional and ornamental cylinder characteristics. We have no size limitations: pilot rolls and cylinders up to 25 tons and 7000 mm of engraved length. We are equipped with every engraving technology available on the market; an automated workstation with robotic arm allows us to reduce processing times.

EMBOSS Specifications

Embossing rolls are tailor-made products engineered to meet specific requirements: we offer solutions for any production need by developing technical-functional and ornamental characteristics, producing and engraving the cylinder, supporting our customers in every phase of the roller’s operational life. We have no size limitations: we produce pilot rolls and cylinders up to 25 tons and 7000 mm of engraved length. We are equipped with every engraving technology available on the market and have an automated workstation with robotic arm that allows us to considerably reduce processing times.

Product and process excellence

Product e process excellence

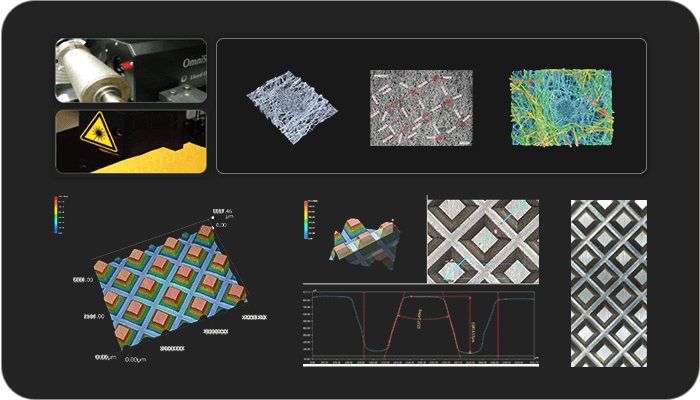

3D DETECTION

Using a high-resolution electron microscope, which returns a 3D image, we detect the pattern design and its different depths, whether it is a product sample or a pre-existing engraving. We identify pin specifications and evaluate possible improvements. Each scan is recorded in a detailed report.

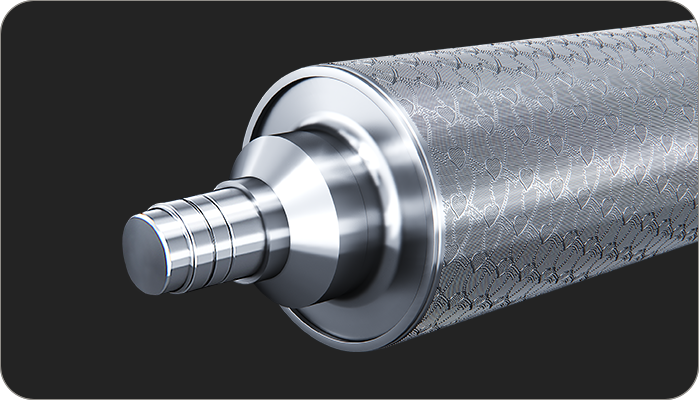

PATTERN DEVELOPMENT

Extensive industry know-how and state-of-the-art technology allow us to transform a photo or Google image into a pattern, as well as to carry out a three-dimensional analysis of a given sample to define its design and engraving specifications. The pattern undergoes a simulation of the vibrations generated by the dynamic interaction between engraved and smooth rollers allowing us to adjust the design to reduce or eliminate its negative effect.

ENGRAVING STRATEGY

During the development of a new pattern it is also important to evaluate the best engraving strategy depending on the type of line, the size of the cylinder and the material to be engraved, whether soft or pre-hardened. A simulation highlights potential production problems: the choice between a mechanical, chemical, laser or combined process will also determine the costs and timing of the engraving process.

What's the Cylinder meeting your needs?

What's the Cylinder meeting your needs?

NONWOVEN

We offer operators in the nonwoven industry rollers with weights up to 25 tons and up to 7000 mm engraved length. We carry out traditional mechanical, chemical, laser and combined engravings. We support our customers from the development of an idea to after sales consultancy: pattern design, reverse engineering, prototyping, vibration simulation, calender roll engraving, coating and engraving of compaction rolls, kiss rolls engraving, anilox for printing, drag rollers and foulard rollers.

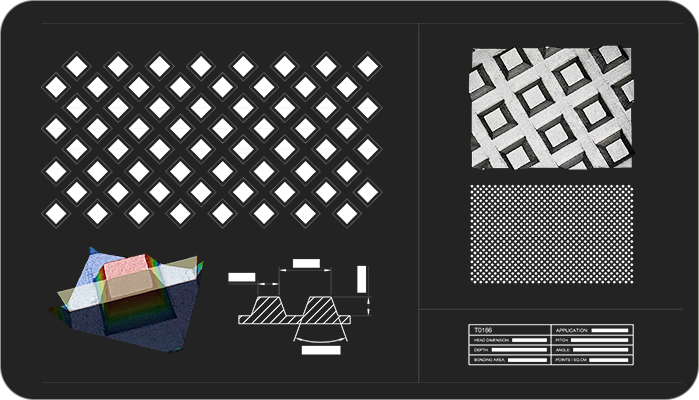

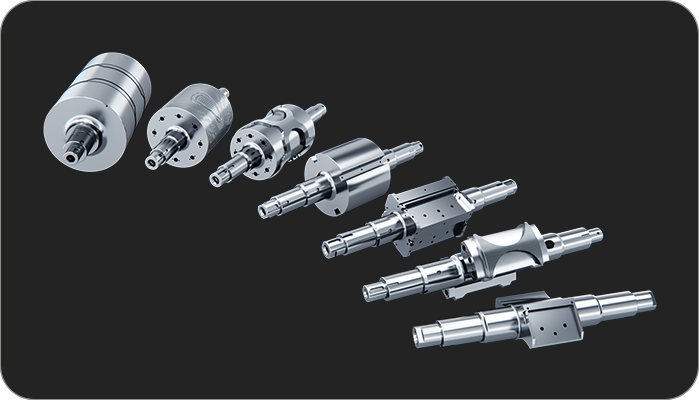

ULTRASONIC BONDING

We meet the needs of the operators in the entire Medical & Personal Care supply chain, acting as a core point for the supply of the cylinders to be marketed. We offer cuff rollers, ultrasonic anvil and anvil rollers, multi-layer and multi-pattern rollers, endcut, crimping and counter rollers.

TECHNICAL FILM

The know-how acquired in the micro-embossed film enabled us to develop exclusive production processes, specific galvanic treatments, a wide range of standard and customized engravings and technologies for chemical matting suitable for the purpose.

Rollers for breathable backsheet film; laminated backsheet film; barrier and backsheet film; breathable laminated backsheet film; film for sanitary napkins.

TISSUE CONVERTING

We offer cylinders engraved with different technologies to both OEMs and end-users operating in the tissue converting industry: micro-engraving by mechanical process, chemical engraving and combined solutions. We have no dimensional limitations: we can process engraved lengths up to 7000 mm and diameters up to 900 mm. We process pre-hardened materials and steel with galvanic chrome coating. Our portfolio includes also anilox rolls for printing and cylinders for ply coupling.

TISSUE FOLD

We have introduced a line of embossing rolls, engineered for both OEMs and end-users operating in the tissue fold industry, thus completing the product range for the Tissue industry. We offer every types of engraving: those to meet the specific needs of single-ply products, continuous engravings, engravings with ornamental elements and those dedicated to paper napkin manufacturers.

© 2019 Simec Group Srl Via Verga, 17 – 21057 Olgiate Olona (VA) – +39 0331 393900

Share Capital Euro 2.000.000,00 i.v. – R.E.A Varese n. 335797 – VATIN: IT03252460120