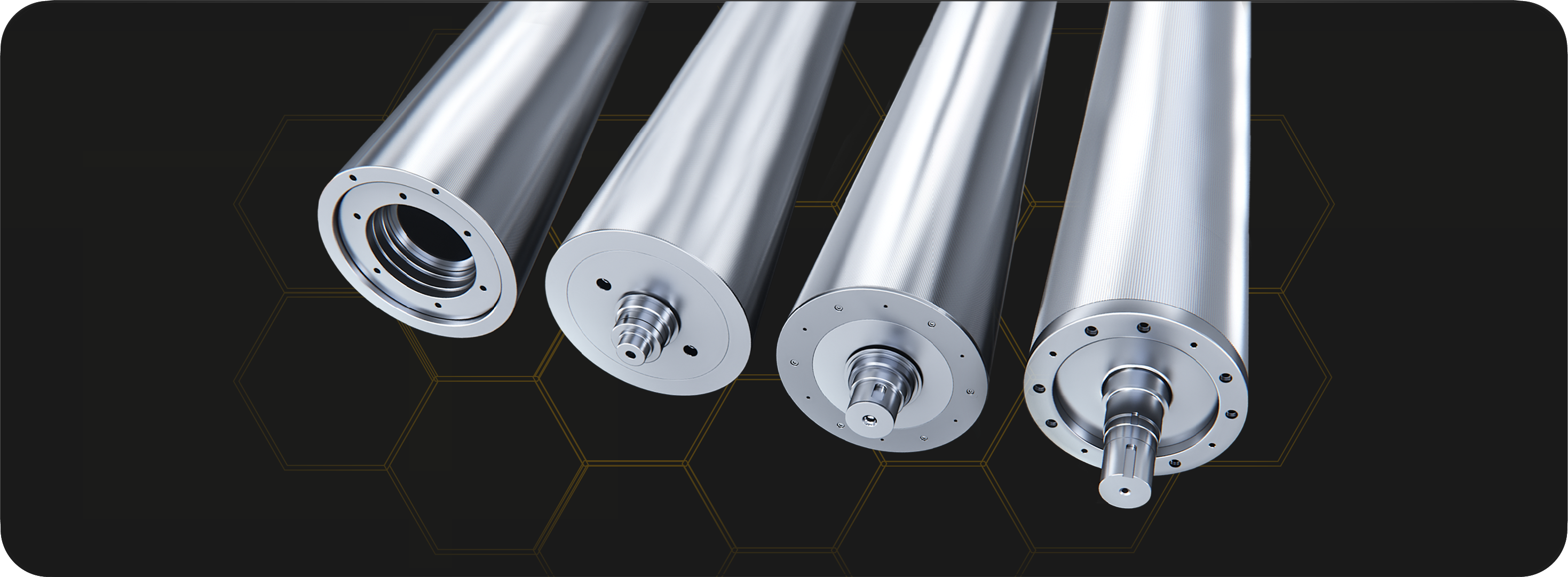

We are leader in the manufacturing and refurbishment of high-quality glue and doctor rollers for corrugated cardboard coupling. We develop customized solutions for the aftermarket service of the industry’s primary equipment manufacturers. We offer a wide range of engravings, new on-demand configurations and ad-hoc solutions for excellent product release and reduction of cells clogging problems.

We are leader in the manufacturing and refurbishment of glue and doctor rollers. We develop customized solutions for the aftermarket service of the industry’s primary OEMs. We offer a wide range of engravings, new on-demand configurations and ad-hoc solutions for excellent product release and reduction of cells clogging problems.

We supply the leading OEMs in this industry. 6 production lines dedicated to this application, processing a total of 800 rollers per year. 50+ types of engraving designed for this industry, special ones available, detection and reproduction of any geometry. Tight tolerances guarantee excellent quality and full control of product release.

We offer a wide range of deposition technologies, including galvanic coatings such as chrome, nickel and copper; welding coatings such as carbon-steel, stainless steel and alloys; and thermal spray coatings such as wire copper or other materials.

We supply the leading OEMs in this industry. We have 6 production lines dedicated to this application, processing a total of 800 rollers per year. Over 50 types of engraving designed for this industry are available or just ask for special ones, developed to meet your specific needs; our technology allows us to detect and reproduce any geometry. Tight tolerances guarantee excellent quality and full control of product release.

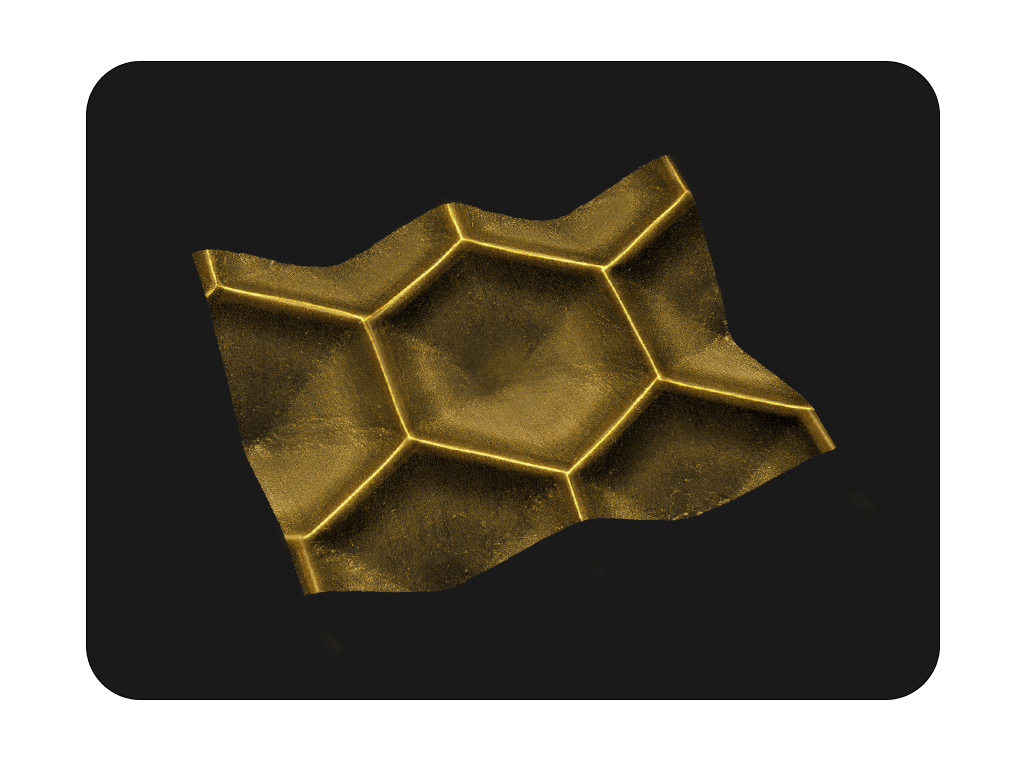

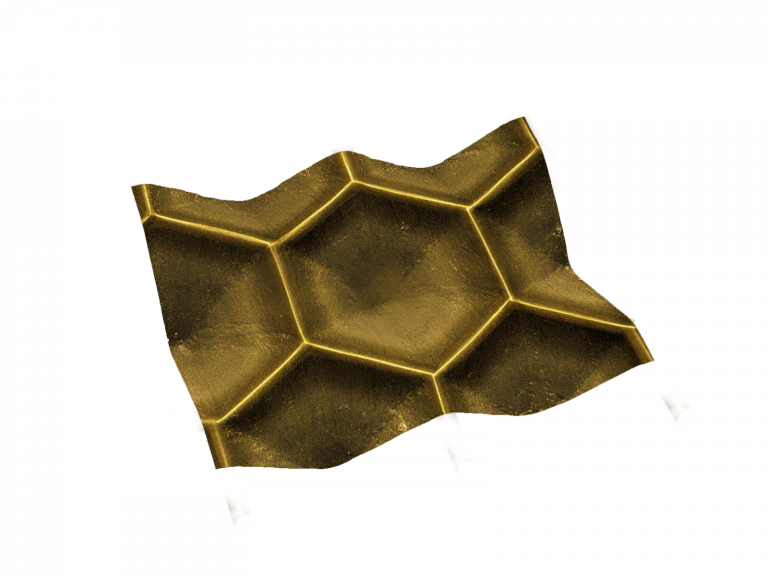

Engraving

Hexagon

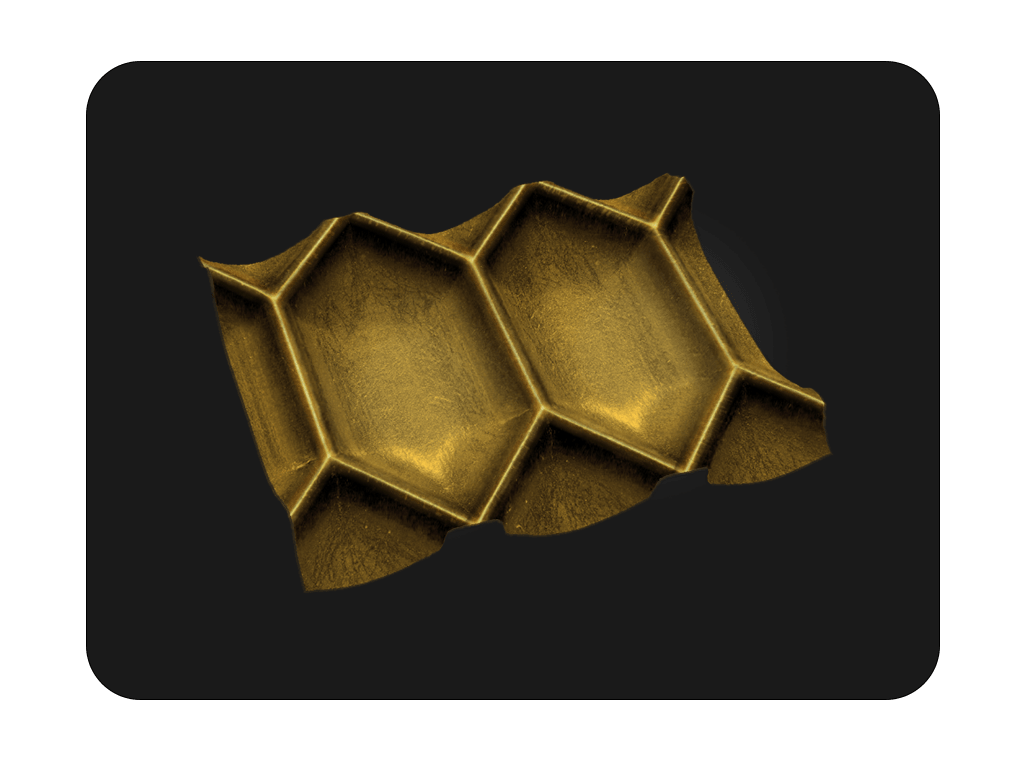

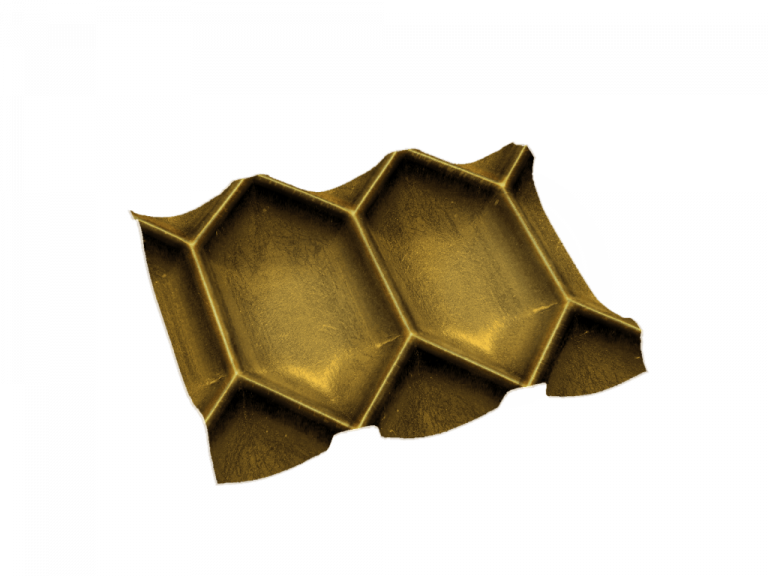

Engraving

Double Cell

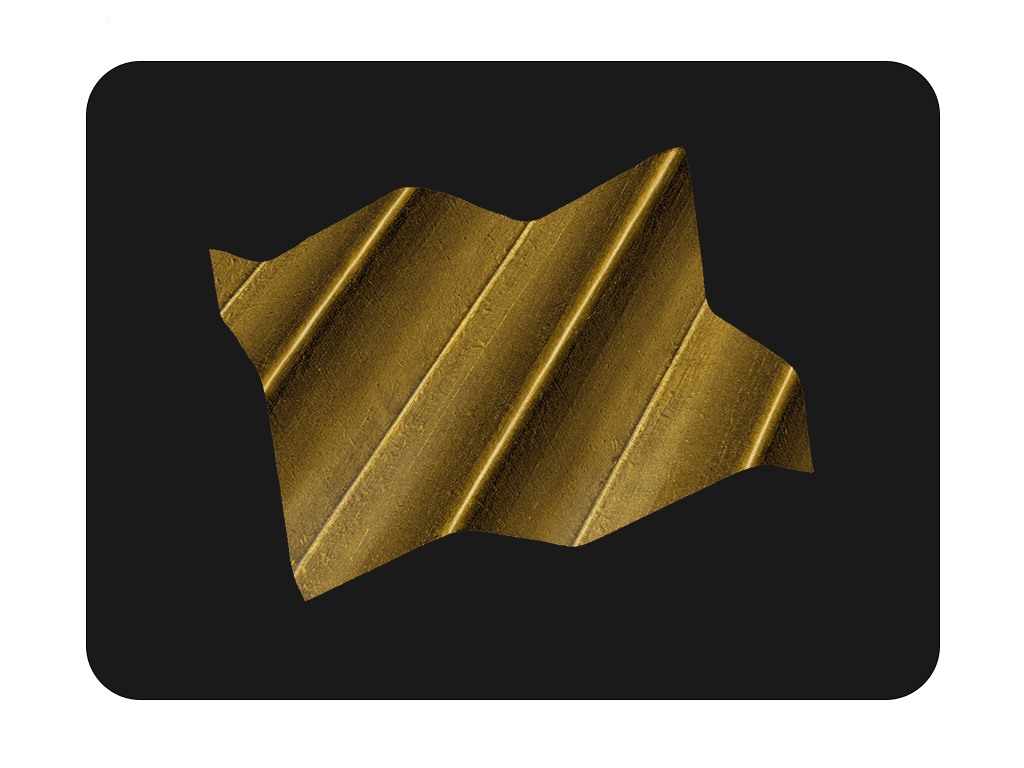

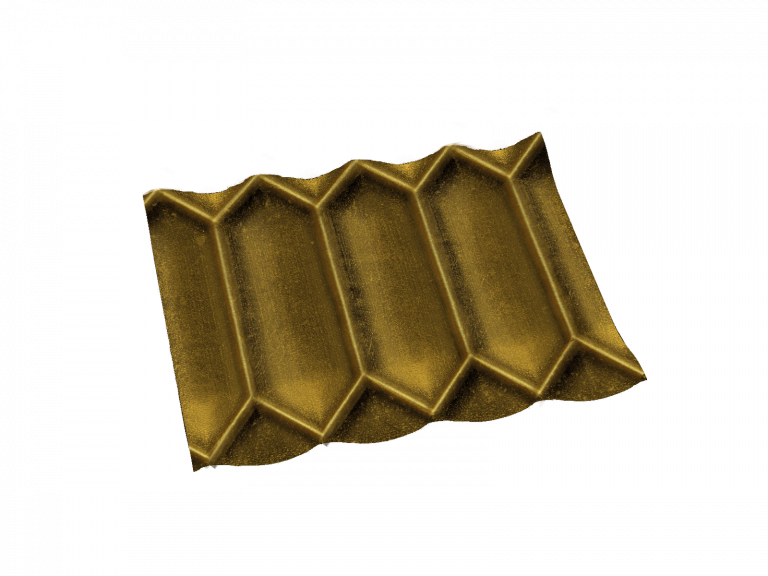

Engraving

Truncated Pyramid

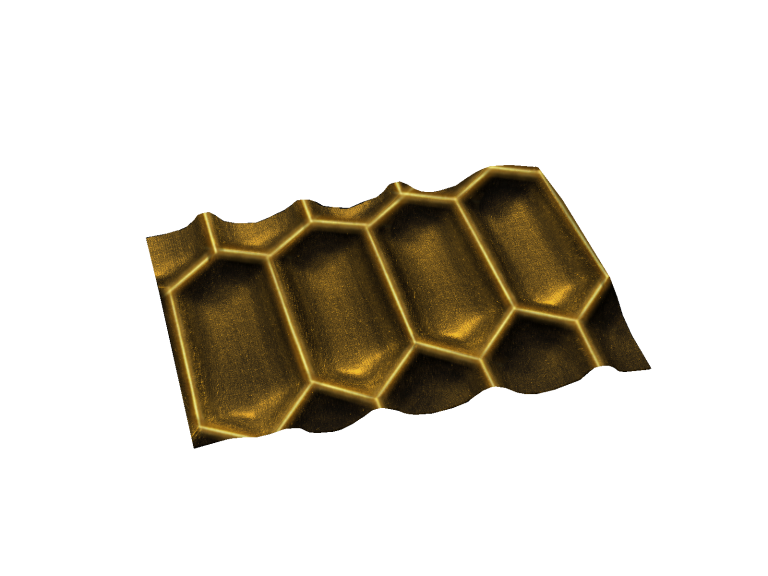

Engraving

Triple Cell

Engraving

Brick

We offer a wide range of deposition technologies, including galvanic coatings such as chrome, nickel and copper; welding coatings such as carbon-steel, stainless steel and alloys; and thermal spray coatings such as wire copper or other materials.

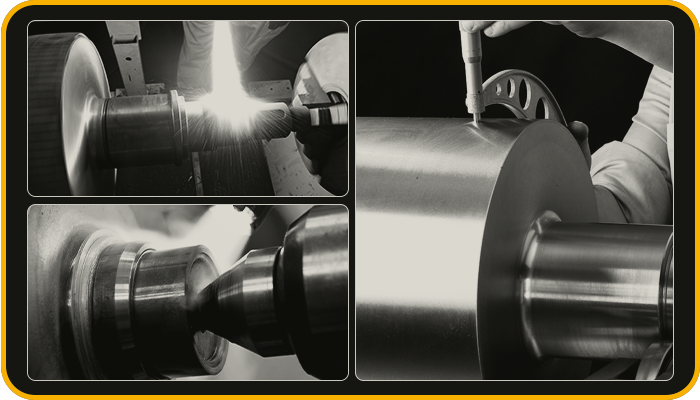

Our procedures ensure that a refurbished roller has the same performance and operating life as a new one. All machining operations follow the OEM specifications recorded in our database. Each anilox has an ID card where all significant steps in its life cycle are recorded, allowing us to analyse its performance over time.

The refurbishment of mechanically engraved chromed rollers implies the roller diameter reduction. If required by OEMs' manufacturing specifications, we restore the diameter and apply a substrate such as nickel, steel or stainless steel, depending on the model and on the requirements of the machine on which the roll will be installed.

© 2019 Simec Group Srl Via Verga, 17 – 21057 Olgiate Olona (VA) – +39 0331 393900

Share Capital Euro 2.000.000,00 i.v. – R.E.A Varese n. 335797 – VATIN: IT03252460120

laser engraved rollers & sleeves

mechanically engraved rollers

embossing rollers

laser engraved special