Aluminium

Industries Served

Aluminium

Industries Served

Aluminium

For those in the aluminium industry, who produce foil for food& beverage applications, we offer technologically advanced products with traditional or ad-hoc developed patterns to differentiate the product on the shelf. Bottle collars, thin food contact foils, laminates and container lids – whatever the need, we have a solution.

For those in the aluminium industry, who produce foil for food& beverage applications, we offer technologically advanced products with traditional or ad-hoc developed patterns to differentiate the product on the shelf. Bottle collars, thin food contact foils, laminates and container lids – whatever the need, we have a solution.

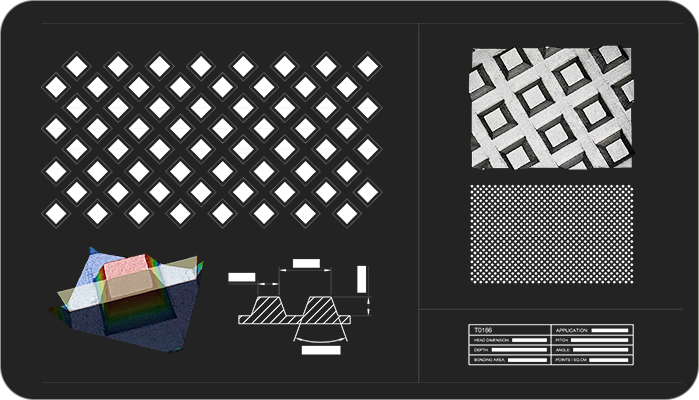

EMBOSS for Aluminium

Thanks to the expertise acquired in the many industries we serve, our technical capabilities and our production facilities, we can supply embossing cylinders for aluminium made of different materials and engraved with diverse technologies: engraving into steel or ceramic, with micro-machining, with direct laser, chemical or combined engraving, chromium-plating and ad-hoc superfinishing.

EMBOSS for Aluminium

Thanks to the expertise acquired in the many industries we serve, our technical capabilities and our production facilities, we can supply embossing cylinders for aluminium made of different materials and engraved with diverse technologies: engraving into steel or ceramic, with micro-machining, with direct laser, chemical or combined engraving, chromium-plating and ad-hoc superfinishing.

Technology applied to Aluminium

Technology for Aluminium

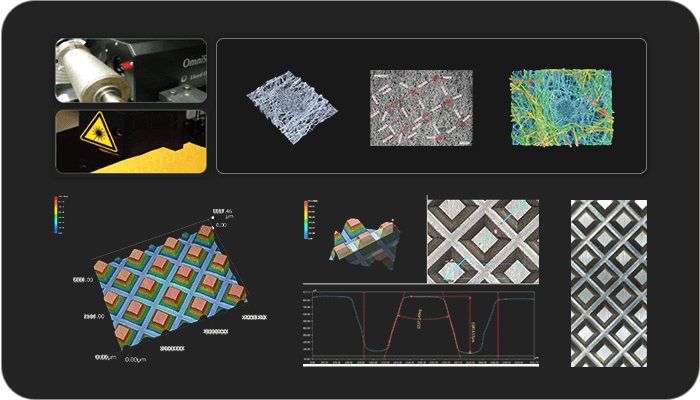

3D DETECTION

Using a high-resolution electron microscope, which returns a 3D image, we detect the pattern design and its different depths, whether it is a product sample or a pre-existing engraving. We identify pin specifications and evaluate possible improvements. Each scan is recorded in a detailed report.

PATTERN DEVELOPMENT

Extensive industry know-how and state-of-the-art technology allow us to transform a photo or Google image into a pattern, as well as to carry out a three-dimensional analysis of a given sample to define its design and engraving specifications. The pattern undergoes a simulation of the vibrations generated by the dynamic interaction between engraved and smooth rollers allowing us to adjust the design to reduce or eliminate its negative effect.

ENGRAVING STRATEGY

During the development of a new pattern it is also important to evaluate the best engraving strategy depending on the type of line, the size of the cylinder and the material to be engraved, whether soft or pre-hardened. A simulation highlights potential production problems: the choice between a mechanical, chemical, laser or combined process will also determine the costs and timing of the engraving process.

© 2019 Simec Group Srl Via Verga, 17 – 21057 Olgiate Olona (VA) – +39 0331 393900

Share Capital Euro 2.000.000,00 i.v. – R.E.A Varese n. 335797 – VATIN: IT03252460120